How 2026 TPU Films Maintain Clarity on White Paint

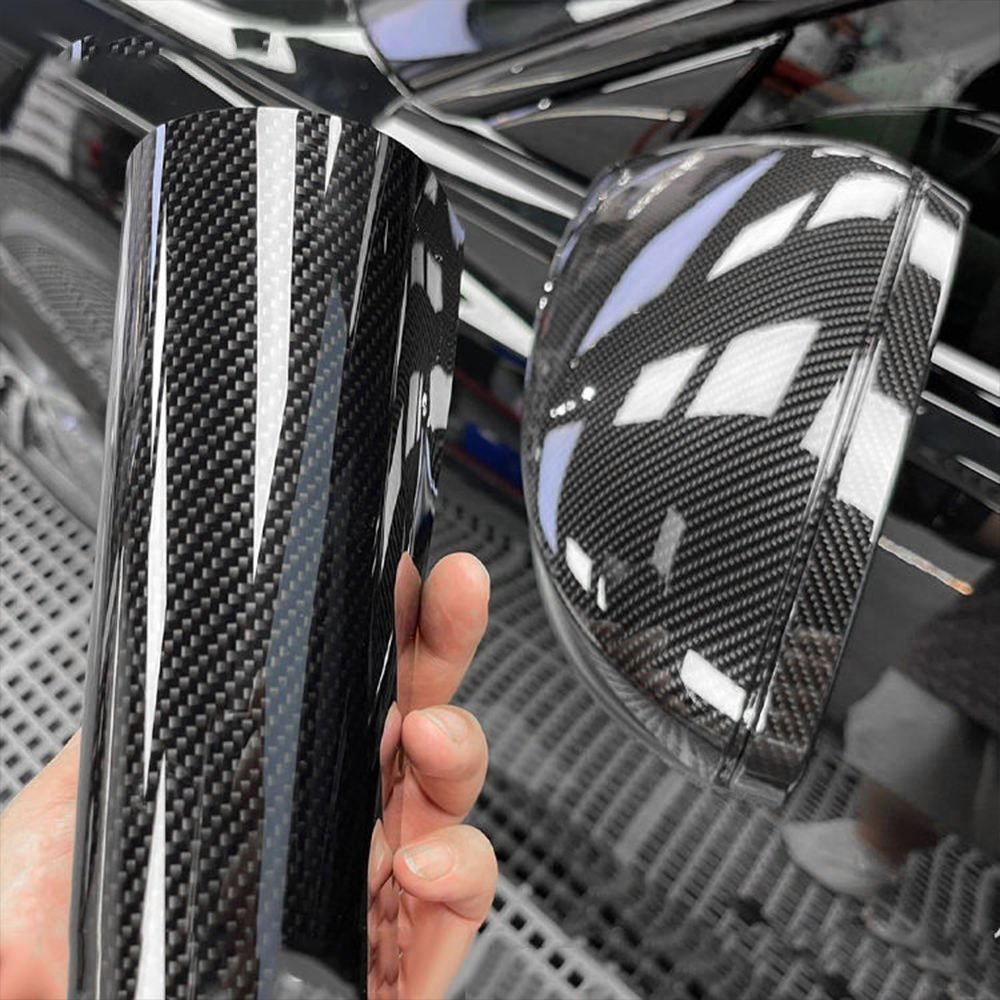

In the automotive and industrial sectors, the demand for clear protective films that maintain their transparency over white painted surfaces is growing. The 2026 generation of thermoplastic polyurethane (TPU) films addresses this challenge through advanced material science and innovative manufacturing techniques.

Material Composition Innovations

The core innovation lies in the molecular structure of the TPU polymer. New formulations incorporate:

- UV-stabilized monomers that resist yellowing

- Optical-grade plasticizers that prevent haze formation

- Proprietary crosslinking agents that enhance clarity

These components work synergistically to maintain optical clarity even when applied over bright white paint surfaces.

Manufacturing Process Enhancements

The 2026 production process includes:

- Multi-stage purification systems that remove contaminants

- Precision calendering techniques that create uniform thickness

- Advanced surface treatment methods that improve adhesion without affecting clarity

Performance Characteristics

Key advantages include:

- Long-term clarity retention: maintains >90% light transmission after 5 years of exposure

- Paint compatibility: specially formulated to prevent color bleed-through

- Self-healing properties: minor scratches disappear at ambient temperatures

- Environmental resistance: withstands extreme temperatures and chemical exposure

Application Benefits

When applied to white surfaces, these films:

- Preserve the original paint brilliance

- Eliminate the “milky” appearance common with older films

- Provide superior protection against stone chips and environmental damage

- Maintain clarity even after repeated cleaning cycles

Future Outlook

As automotive design trends toward brighter white finishes, the 2026 TPU films set new standards for protective coatings. Their ability to maintain clarity while offering superior protection makes them ideal for high-end vehicles and industrial applications where appearance preservation is critical.