The most direct and effective way to determine whether TPU PPF is starting to turn yellow is visual comparison and professional testing. Let me explain in detail these 5 commonly used methods to help you quickly judge:

1. Visual comparative testing method

Key points of operation: Take the leftover scraps of the car clothes (such as the hidden area inside the trunk) that are kept during construction, compare them with the same part of the car body in sunlight, and observe the color difference at a 45 ° angle.

Key inspection areas: engine hood, roof and other exposed areas, yellowing areas will refract warm tones under strong light.

2. Professional equipment testing method

Chromatic aberration measurement: Use equipment such as X-Rite Ci64 to detect the color difference value Δ E. When Δ E>2.0, it can be detected by the naked eye. If Δ E>5.0, it needs to be replaced.

UV lamp test: Using a 365nm UV lamp in a dark room to irradiate the car film, the yellowing area will show more obvious yellow patches due to fluorescence reaction.

3. Performance degradation verification method

Self repair test: Use fine sandpaper to lightly scratch the surface of the car cover, observe the speed of scratch disappearance under 60 ℃ hot water or sunlight. High quality car covers should be repaired within 30 seconds, and the repair time for yellowing car covers is significantly extended.

Weather resistance assessment: Conduct laboratory QUV accelerated aging test, simulate 1000 hours of ultraviolet irradiation, and observe the amplitude of color change.

4. UV lamp testing method

Operation points: Use a 365nm ultraviolet lamp to irradiate the car clothes in a dark room, and the yellowing area will show more obvious yellow patches due to fluorescence reaction.

5. Weather resistance evaluation method

Key points of operation: Conduct QUV accelerated aging test in the laboratory, simulate 1000 hours of ultraviolet irradiation, and observe the amplitude of color change.

Yellowing grading response strategy

Grade 1 yellowing (Δ E<2.0): Strengthen daily maintenance, such as regular cleaning and application of specialized care agents.

Secondary yellowing (2.0<Δ E<5.0): Consider partial replacement or reconstruction.

Level 3 yellowing (Δ E>5.0): Replace the entire vehicle’s clothing.

Three stages of yellowing development

Initial stage: Minor color difference, light transmittance decreases to below 90%.

Mid term: Significant yellowing and a decrease in transmittance to below 80%.

Post production: The entire car’s exterior is dark yellow or amber in color, with a decrease in light transmittance to below 80%. The material becomes hard and brittle, with slight scratches leaving marks. The self-healing function is basically ineffective, and the hydrophobicity is completely lost.

How to choose a truly anti yellowing car wrap

Material identification: Merchants are required to clearly label the TPU type (aliphatic/aromatic).

View third-party testing report: View yellowing index data.

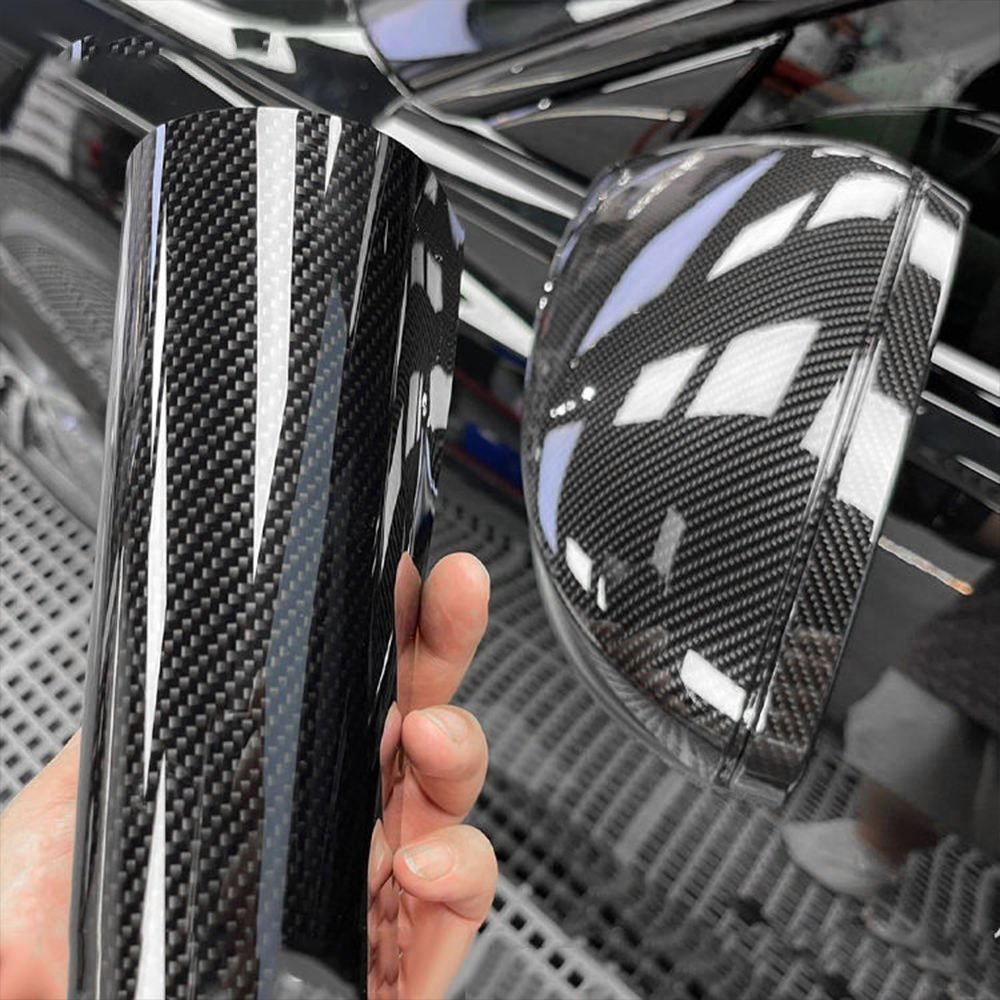

On site inspection of samples: Investigating the aging test effect of the samples.