TPU PPF thickness is a critical factor in determining the performance, durability, and application suitability of paint protection films (PPF) for vehicles. As thermoplastic polyurethane (TPU) becomes the dominant material in PPF due to its exceptional elasticity, self-healing properties, and UV resistance, understanding thickness variations is essential for both consumers and professionals in the automotive detailing industry. This article explores the significance of TPU PPF thickness, its measurement standards, and how it impacts film performance across different vehicle surfaces.

Why TPU PPF Thickness Matters

The thickness of TPU PPF directly influences several key performance characteristics:

Impact Resistance: Thicker films (typically 8 mil and above) provide superior protection against stone chips, road debris, and minor abrasions. This is particularly important for high-speed driving or off-road vehicles.

Self-Healing Properties: While all TPU PPFs have some self-healing capability, thicker films maintain this functionality better over time and across wider temperature ranges.

Application Ease: Thinner films (6-7 mil) are generally easier to install, especially on complex curves and contours, making them popular among professional installers.

Longevity: Thicker films tend to have longer useful lives, offering better protection against environmental degradation and maintaining clarity over extended periods.

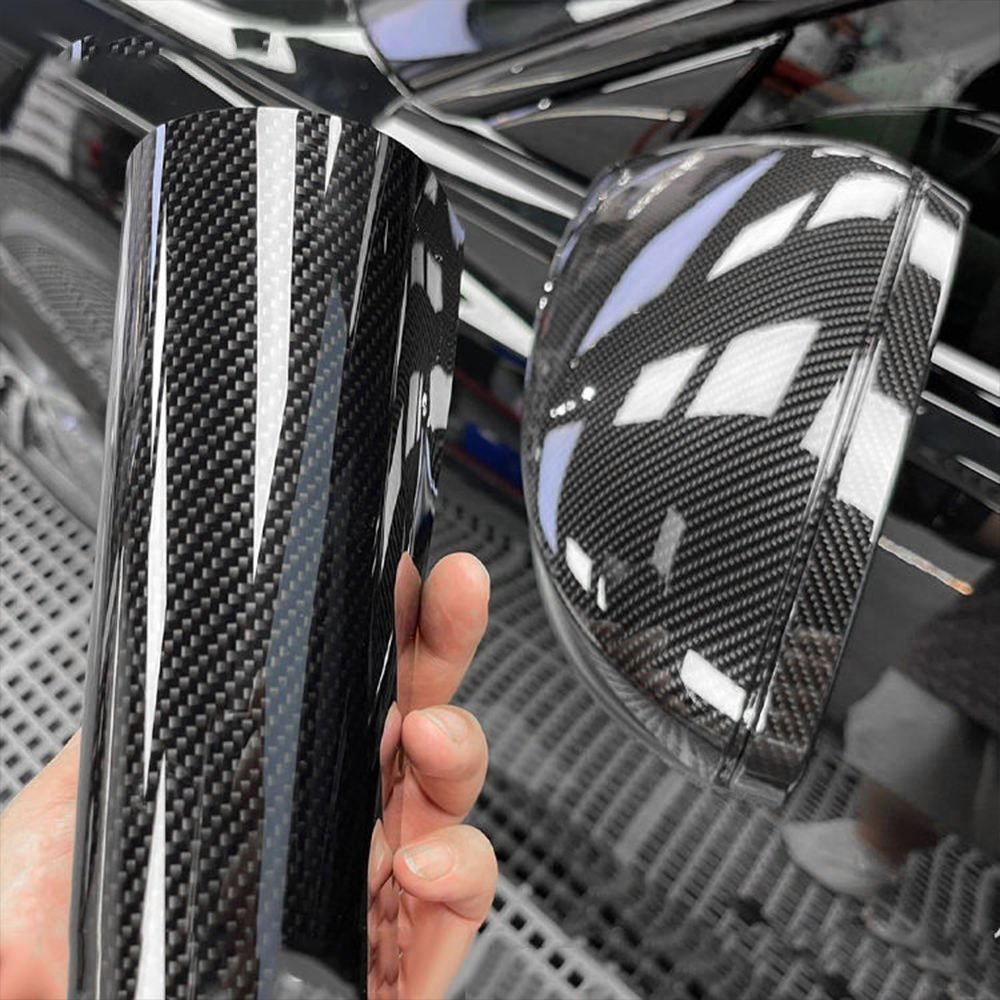

Aesthetics: Thicker films can sometimes create a more pronounced “wet look” effect on vehicle surfaces, which some consumers find desirable.

Standard TPU PPF Thickness Options

The industry offers several standard thickness options for TPU PPF, each catering to specific needs:

1. Standard Thickness (6-7 mil)

- Most common for everyday passenger vehicles

- Balances protection and application ease

- Suitable for most body panels and surfaces

- Typically used for full-frontal protection or full-car applications

2. Extra Thick (8-10 mil)

- Designed for high-impact areas like hoods, roofs, and front bumpers

- Provides enhanced protection against severe road conditions

- More challenging to install on complex surfaces

- Often used in combination with standard thickness films

3. Ultra-Thin (5 mil or less)

- Primarily used for clear bras on motorcycles and bicycles

- Offers basic protection while maintaining flexibility

- Not recommended for high-speed vehicles or harsh environments

Measuring TPU PPF Thickness

Accurate measurement of PPF thickness is crucial for quality assurance and performance evaluation. The industry standard measurement method is:

- Micrometer Measurement: Using a precision micrometer to measure the film’s thickness at multiple points.

- Calibration: Instruments must be calibrated against known standards before use.

- Multiple Point Testing: Measurements should be taken at various locations across the film roll to ensure consistency.

- Environmental Conditions: Measurements should be conducted in controlled environments (typically 23°C ± 2°C and 50% ± 5% relative humidity) for accuracy.

Thickness Variations Across Brands

Different manufacturers offer their own proprietary thickness options:

- XPEL Ultimate Plus: 8.5 mil thickness with self-healing properties

- SunTek MAX: 8 mil thickness with enhanced clarity

- 3M Scotchgard Pro Series: TPU PPF 7.5 mil thickness with advanced adhesive technology

- Llumar Paint Protection Film: 8 mil thickness with ceramic coating integration

How Thickness Affects Installation

The thickness of TPU PPF significantly impacts the installation process:

- Application Complexity: Thicker films require more skill and experience to apply smoothly without bubbles or wrinkles.

- Drying Time: Thicker films may require longer drying times for the adhesive to properly bond.

- Edge Sealing: Proper edge sealing is more crucial with thicker films to prevent peeling.

- Contour Following: Thinner films adapt better to complex vehicle contours and curves.

Maintenance Considerations Based on Thickness

Different thicknesses require varying maintenance approaches:

- Thicker Films (8-10 mil): May require more frequent cleaning and inspections due to their increased surface area and potential for dirt accumulation.

- Standard Films (6-7 mil): Generally easier to maintain with regular washing and occasional detailing.

- Thin Films (5 mil or less): While low maintenance, they may require more frequent replacement due to their reduced protective capabilities.

Future Trends in TPU PPF Épaisseur

The industry is continuously evolving, with several trends emerging in TPU PPF thickness:

- Hybrid Films: Combining different thicknesses in a single application for optimal protection and flexibility.

- Smart Thickness: Films that adjust their thickness based on environmental conditions or impact intensity.

- Enhanced Adhesives: Developments in adhesive technology that allow for thicker films with easier application.

- Eco-Friendly Thickness Options: Films that maintain protective qualities while using less material.

Conclusion

TPU PPF thickness plays a pivotal role in determining the performance, application, and longevity of paint protection films. While thicker films offer enhanced protection, they may present installation challenges and require more maintenance. Conversely, thinner films are easier to apply but may not provide the same level of durability. Understanding these thickness variations and their implications allows consumers and professionals to make informed decisions when selecting PPF for different vehicle surfaces and applications. As technology advances, we can expect to see continued innovation in TPU PPF thickness options, offering even better protection and application experiences for vehicle owners worldwide.