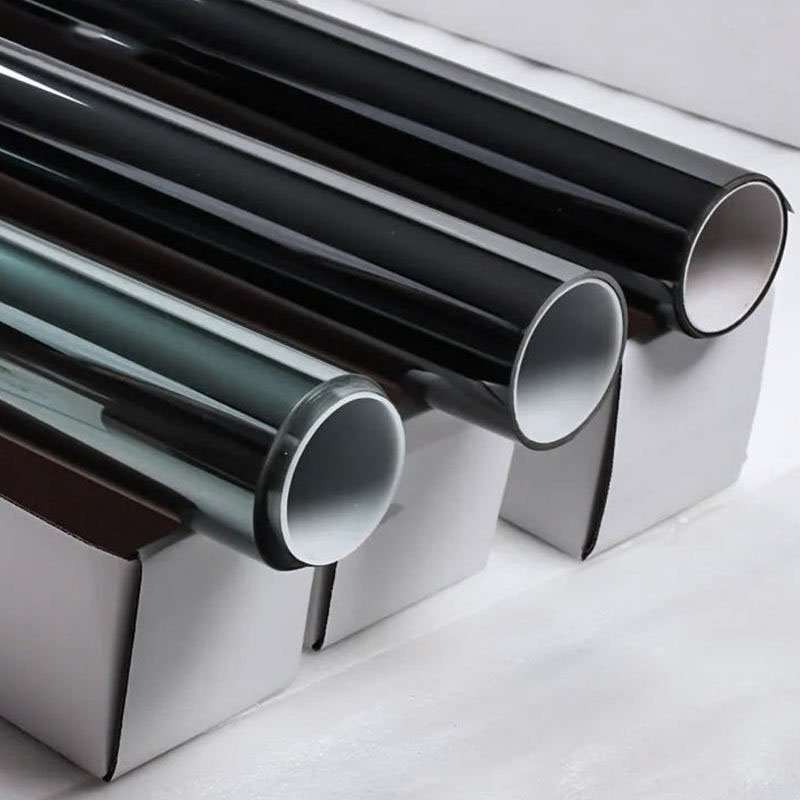

The mainstream materials for windshield tint film are multi-layer metal film and ceramic film:

Metal film: Magnetron sputtering technology, strong insulation (such as quantum diamond 70 insulation rate of 55%), but may slightly interfere with the signal

Ceramic film: Nano ceramic coating (such as dragon film crystal 80 with a thermal insulation rate of 47%), no signal shielding, suitable for new energy vehicles

Key parameters: Transmittance should be ≥ 70%, and UV blocking rate is recommended to be above 99%

PET substrate: Mainstream automotive ceramic films (such as Meiji V10 titanium nitride ceramic film) use polyethylene terephthalate (PET) as the substrate, and ceramic particles such as titanium nitride and zirconia are implanted into the substrate through magnetron sputtering or nanotechnology to form a multi-layer composite structure. This design combines high transparency (≥ 70%) and strong thermal insulation

Structural features: It usually includes a wear-resistant layer (4H hardness), a metal layer (vacuum aluminum plating), and an adhesive layer (pressure-sensitive adhesive). Some products adopt a “shallow front and deep back” gradient design

Yüksek kaliteli PET substrat partikülleri ve ithal marka yapıştırıcılar

Different Window tint are compatible with a 3-5 year warranty

CE ve ROHS sertifikalı, çevre dostu ve güvenli

Spot malların hızlı teslimatı, yaklaşık 7-15 gün, deniz ve hava taşımacılığını destekler

| Comparison Item | Metal Film | Ceramic Film |

| Heat Insulation | Reflective insulation, 61% IR reflectivity | Absorptive insulation, stable performance |

| Signal Interference | May block GPS/ETC signals | No metal layer, no signal interference |

| Durability | Prone to oxidation, 5-year warranty | Oxidation-resistant, 5–10-year warranty |

| Light Transmittance | Darker tint, may affect visibility | High transparency, clear vision |

| Price | Cost-effective | Technologically costly, relatively expensive |

| Product | Car window tint film |

| Material | PET |

| Kalınlık | 2 mil |

| Boyut | 1.52*30 m |

| VLT | 15 |

| UVR | 99 |

| IRR | 92 |

| TSER | 89 |

Car color changing film is a thin film material applied to the surface of a car, which can change the color of the car body without damaging the original paint, while providing certain protective functions. According to the different materials and functions, TPU color changing film has high-end materials and combines color changing and invisible car clothing functions

The mainstream materials for windshield film are multi-layer metal film and ceramic film, with the specific material composition as follows:

1. The multi-layer metal film adopts magnetron sputtering technology to uniformly sputter rare metals such as gold, silver, titanium, nickel, chromium, etc. onto the PET substrate.

2. In the field of automotive ceramic film, PET (polyethylene terephthalate) is commonly used as the substrate, such as the Meiji V10 titanium nitride ceramic film, which implants titanium nitride ceramic particles into the PET substrate.

1. Avoid washing the edges with high-pressure water guns: Do not wash the car within 10 days after applying the film, and it is not recommended to wash the car within 7 days,

2. Timely cleaning of stubborn stains: Corrosive stains such as oil stains and gum should be cleaned within 24 hours,

3. Avoid extreme environments: Long term exposure to sunlight or uneven heating and cooling can accelerate aging

1. The price of cost-effective and economical TPU invisible car wrap ranges from $250 to $400 per roll.

2. Using imported aliphatic TPU Base material, specially designed for luxury car models priced over 300000 yuan, with strong protective performance and a 10-year warranty. The car film cost is about $500 per roll.

3. Multi layer composite TPU material, suitable for million level luxury cars or vehicles with special process requirements, priced at approximately $1000 per roll.