Abstract

Thermoplastic Polyurethane (TPU) Paint Protection Film (PPF) is widely valued in automotive and industrial applications for its self-healing properties and durability. However, yellowing remains a significant concern that affects aesthetic longevity and performance. This paper examines the chemical mechanisms behind TPU PPF yellowing—primarily photo-oxidative degradation and UV exposure—and evaluates practical strategies to mitigate this issue through advanced polymer stabilization technologies.

Introduction

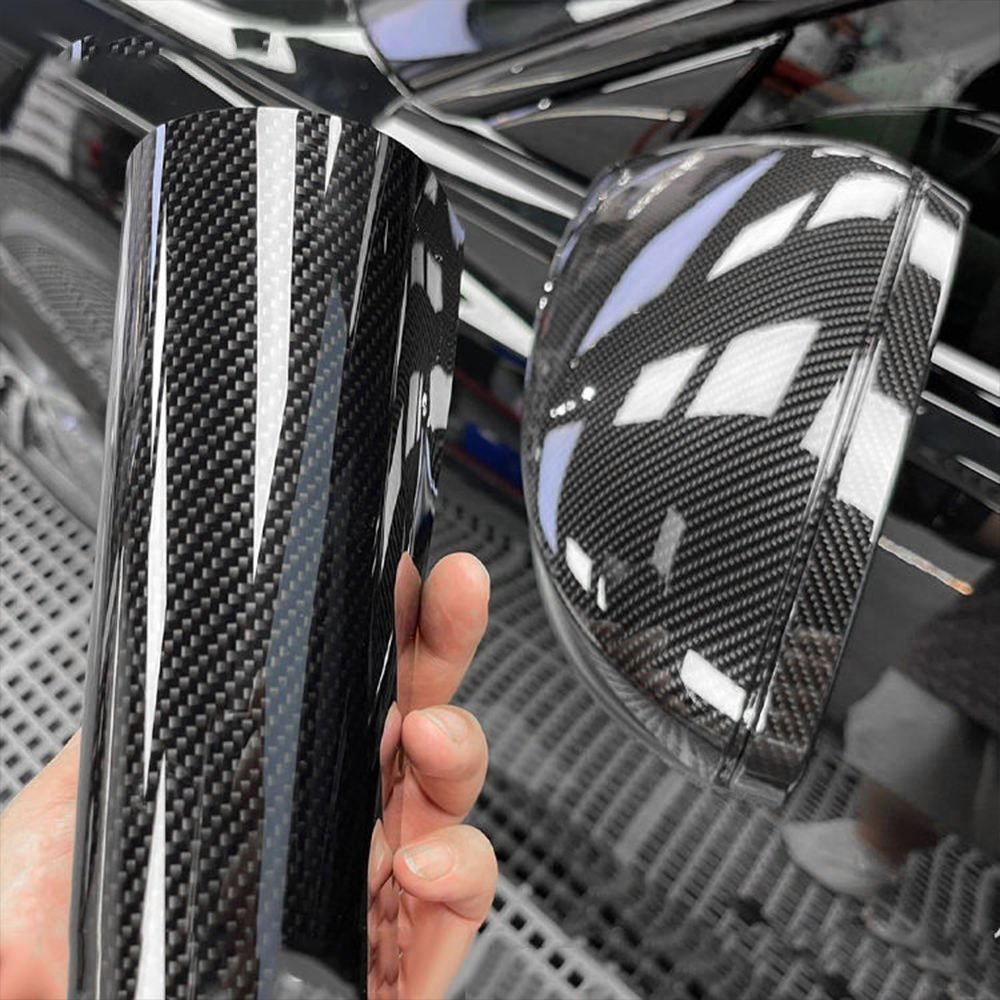

TPU-based PPF serves as a protective layer against scratches, stone chips, and environmental contaminants. Despite its resilience, prolonged exposure to external factors can induce yellowing, undermining its optical clarity. Understanding whether TPU PPF turns yellow involves analyzing material science principles and environmental interactions. This paper addresses the causes, consequences, and countermeasures related to yellowing in TPU PPF.

Causes of Yellowing in TPU PPF

Yellowing in TPU PPF stems from multiple sources:

- UV Radiation: Solar UV rays break down polymer chains, leading to the formation of chromophores that absorb blue light, resulting in a yellow appearance.

- Oxidation: Oxygen interaction with TPU’s molecular structure, especially in the presence of heat or pollutants, accelerates degradation.

- Additive Instability: Certain plasticizers or unstabilized polymers may oxidize over time, contributing to discoloration.

- Environmental Contaminants: Industrial fallout, acid rain, or improper cleaning agents can catalyze chemical reactions that promote yellowing.

Preventive Technologies and Solutions

Modern TPU PPF formulations integrate advanced technologies to resist yellowing:

- UV Stabilizers: Additives like hindered amine light stabilizers (HALS) and UV absorbers scavenge free radicals and minimize photo-degradation.

- Anti-oxidants: These compounds inhibit oxidative chain reactions, preserving the polymer’s intrinsic color.

- Hydrophobic Top Coats: Nano-ceramic or silicone-hardened layers repel contaminants and reduce adherence of yellowing agents.

- Polymer Engineering: Optimizing the polyol and diisocyanate ratios during TPU synthesis enhances inherent UV and thermal stability.

Conclusione

While TPU PPF is susceptible to yellowing due to environmental and chemical TPU PPF factory, advancements in polymer science and additive technology have substantially improved its resistance. The industry’s shift towards high-performance, yellowing-resistant PPF ensures extended functional and visual integrity, making modern TPU films a reliable solution for long-term surface protection.